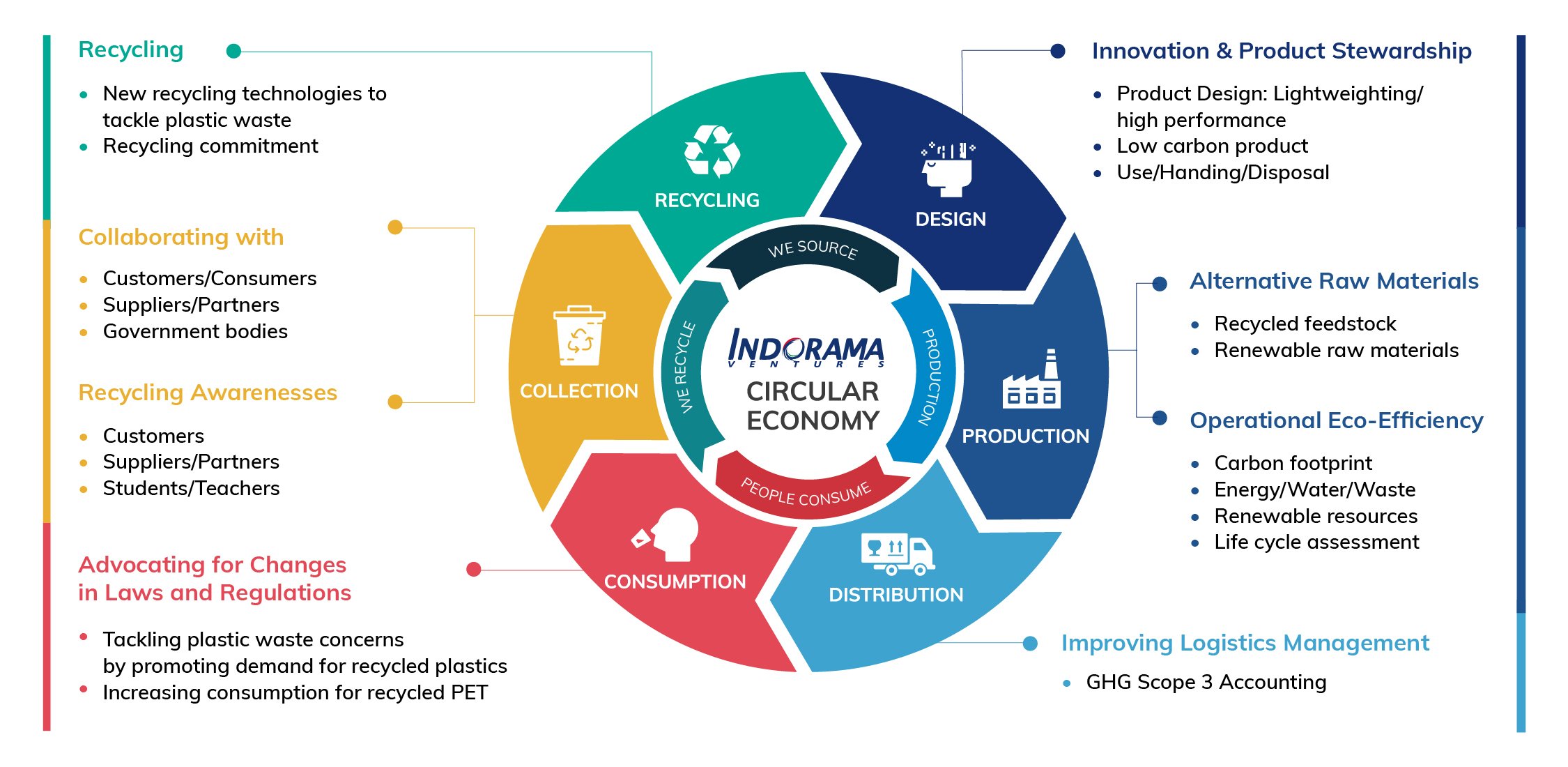

Circular Economy

We intend to reduce the concern consumers have about the impact of PET bottles in the environment, and will achieve this by building collaborative systems to increase the global recycling rate of polyester and investing in recycling capacities. As the largest virgin PET resin producer, we want to compliment this position by becoming the global leader in the recycling of PET bottles and packaging. We will supply our customers PET with their desired levels of recycled content, and in the process will save energy and water and reduce emissions that contribute to global climate change.

The Secrets to Unlocking the Next Frontier for a Circular Economy in the Asia-Pacific Region

(The source of this information is available at https://repository.unescap.org/handle/20.500.12870/7491)

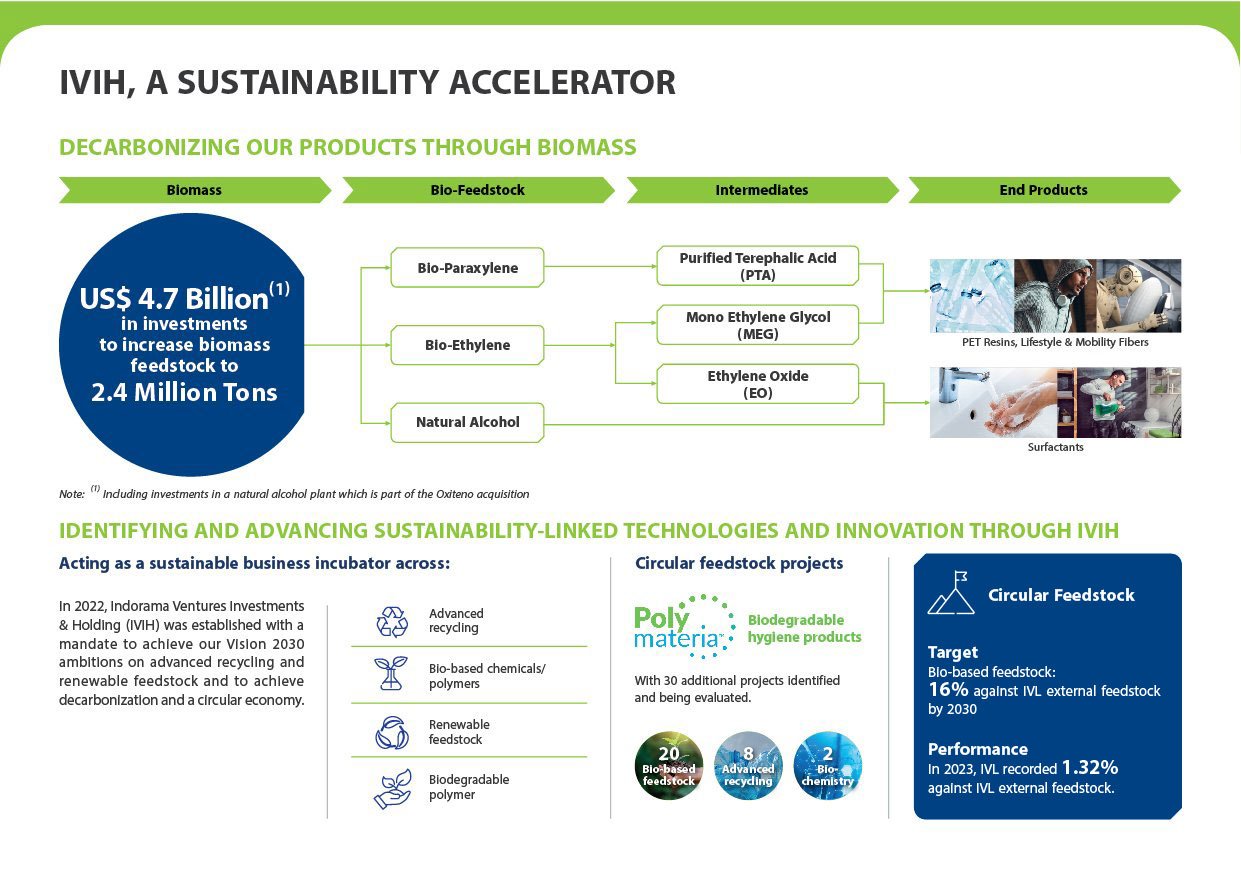

Explore MoreCircular Feedstock

Bio-based feedstock: 16% against IVL external feedstock

Recycled feedstock (Post-consumer PET bale input): 23% against IVL PET feedstock by 2030

2024 Progress

Bio-based feedstock: 1.50% against our external feedstock

Recycled feedstock (Post-consumer PET bale input): 4.94% against our PET feedstock

Circular Economy Achievement

Products are designed to be light weight, achieve high performance in the use phase, and include more sustainable and recycled materials which can be easily managed at their end of life.

CiCLO BIODEGRADABLE TEXTILE TECHNOLOGY

CiCLO is a textile technology that promotes the biodegradation of synthetic fibers, thereby reducing synthetic microfiber pollution in the event that the products are discarded into the ocean, landfills and wastewater.

Operations that aim to reduce GHG emissions by using alternative raw materials and renewable energy as well as minimize resources consumption.

Operational Performance in 2023

- 16 Onsite / Offsite solar installations in China, India, Indonesia, Thailand, Lithuania, USA, Italy and Egypt

- 324,256 tons recycling of post-consumer PET bale input

- Water intensity = 5.21% / ton of production

- Water reused / recycled = 6.96%

Improving Logistics Management / GHG Scope 3 Accounting

Improving Logistics Management / GHG Scope 3 Accounting

- Improving upstream and downstream transportation and distribution

- Shifting from road to rail transportation

- Moving to direct shipments by avoiding intermediary transshipments

Case Study

Ethylene Exchange Solution

Indorama Ventures (Oxide & Glycols) LLC, or IVOG, is IVL’s wholly-owned subsidiary in Clear Lake (Houston), Texas, producing Ethylene Oxide and Ethylene Glycols (EOEG). IVL is also establishing an olefins production site, Indorama Ventures Olefins LLC, or IVOL, in Lake Charles, Louisiana, the neighboring state. The two companies are located 275 miles apart.

To ensure delivery of ethylene to IVOG, which it purchases as raw material, IVOL decide to enter into a 10-year co-producer ethylene exchange, whereby Indorama has the option to provide up to 100% of IVOL’s 420 KT annual ethylene production to a co-producer, for redelivery to mutually agreed upon destinations between the parties. This agreement benefits both IVOL and the coproducer who has excess capacity in Texas and is short of ethylene capacity in Louisiana, and also reduces pipeline transportation expenses for both parties. Moreover, it is ensured that IVOG’s Clear Lake EOEG plant can be adequately supplied in the event of any operating issues at any single cracker without a disruption in supply to IVOG.

Advocating for Changes in Laws and Regulations by providing and promoting waste management and demand for rPET.

Effort to Impel the Use of Recycled PET in Food Packaging

Thai Beverage Industry Association (TBA) with the support of The Coca-Cola system in Thailand, Suntory PepsiCo Beverage (Thailand) Company Limited and Nestlé (Thai) Ltd. Companies in partnership with IVL have announced their collaboration to further encourage regulation amendment that will allow the use of recycled PET in food and beverage packaging in Thailand.

Explore morePromoting Demand for rPET

IVL signs agreement with beauty leader and Food & Beverages Brands to supply Sustainable PET Packaging for a multi-year.

- Supply PET resin made of 100% recycled materials for L’OREAL packaging needs

- L’OCCITANE will meet its 100% recycled bottles goal ahead of schedule

Partnership with the Bangkok Metropolitan Administration (BMA)

In partnership with the BMA’s Education Department, we conducted a sustainable plastic waste management program, training 437 BMA school directors. As of 2022, we have educated 2,445 students at 19 schools across the Bangkok metropolitan region, with a goal to further engage a total of 100 schools in 2023.

Explore moreWaste Hero Education: Reduce to Zero

In partnership with Yunus Thailand, IVL introduced “Waste Hero Education: Reduce to Zero,” a global resource for teachers with 19 well-crafted lesson plans focused on Recycling Fundamentals, Creating Zero Waste, and Building the Circular Economy. Developed by educators and experts from 17 countries and tested internationally, the materials are tailored for students from kindergarten to university levels. We are also collaborating with regional partners to disseminate the materials through global educator and teacher networks.

Explore moreCollaborating with Stakeholders to build Recycling Education Awareness (suppliers / partners / customers / general public / students / teachers / private sector)

IVL encourages recycling and waste separation among children, communities, and consumers through our recycling education programs, which aim to increase their awareness and involvement in protecting the environment for a better future. In 2021, our training programs were arranged in several organizations.

Explore moreTo raise awareness on the value of recycling PET, IVL has cooperated with several partners to collect Post-Consumer PET Bottles and send back to our recycling factory.

GEPP: The IVL Foundation has signed a memorandum of understanding with GEPP on the collection of waste for sustainable recycling, bringing used PET bottles back to an appropriate recycling process, based on the circular economy concept.

Coca-Cola Thailand: IVL collaborated in the “Coke Kor Keun x Central Group Journey to Zero” project, entering an agreement to support the establishment of a waste management system at Central Group department stores. Beverage bottles and other recyclable materials will be sent to partnering companies to be recycled correctly.

Kasetsart University: IVL joined with Kasetsart University by signing a memorandum of understanding in creating awareness of recyclable waste collection among university staff, students and the public as well as initiating proper waste management. The collaboration includes developing learning materials regarding waste separation and plastic waste recycling, creating a mechanism entrapping waste in a watercourse to avoid it leaking into the sea, as well as creating awareness of waste separation.

Bangchak Corporation: IVL and Bangchak Corporation PCL have signed a memorandum of understanding to join the ‘Rak Pan Sook’ Project, a sustainability project supporting the recycling of used PET bottles. Donation points for PET bottles have been set up at over 100 Bangchak fuel stations around Bangkok and the Metropolitan area. They collected PET bottles from their fuel station and sent 600,000 bottles to our recycling plant.

HSBC Thailand: IVL has collaborated with HSBC Thailand to arrange the “Separate PET Bottles to Help Doctors” project, which aims to transform collected post-consumer PET bottles into much-needed PPE suits for medical personnel. Under the project, HSBC has gathered more than 200 kilograms of post-consumer bottles to make 650 recycled PPE suits to be used when treating low-to-medium risk patients.

Indorama Ventures received the “International Textile Manufacturing Federation” or ITMF Award in 2022 in recognition of progress in the area of international collaboration in the textile industry through the project “ReHubs - Initiatives for fiber-to-fiber recycling in Europe” in accordance with the values of the 17 SDGs of the 2030 Agenda for Sustainable Development.

Indorama Ventures participates in the project “Transform Textile Waste into Feedstock” which was developed by TEXAID, with the goal to establish scalable sorting facilities across Europe, the first one with a capacity of 50,000 tons by end of 2024. This will lead to reach a circular textiles economy in Europe by closing a technology gap to ensure high quality feedstock from non-wearable pre-and-post consumer textile waste to be sorted commercially at scale.

Recycling is the Heart of A Sustainable and Future Global Economy

In 2011, our post-consumer PET bale input were recycled 5,418 tons, but by 2023, it had grown exponentially to about 324,256 tons. During this period, we recycled around 109 billion bottles. This worked out to 2.2 million tons of plastic waste not going to landfill, which would cover 3.2 million tons carbon footprint reduction.

IVL adopts various technologies to develop the PET recycling system. In 2022, IVL established three more recycling facilities in Poland, the Philippines, and France, scaling up to 20 recycling facilities worldwide, with a total of 342,961 tons of post-consumer PET bale input recycled

Carbios in partnership with IVL, to build a Bio-recycled PET manufacturing plant in France

Carbios, a French bio-tech company, and Indorama Ventures have teamed up to construct the first industrial-scale enzymatic PET bio-recycling plant in France. This plant will leverage Carbios’ PET bio-recycling technology and will have the capacity to process 50,000 tons of PET waste per year, equivalent to 2 billion PET bottles or 2.5 billion PET trays. Expected to begin operations by 2025,the plant will also generate 150 job opportunities. Additionally, IVL may explore opportunities to employ Carbios’ unique biological recycling process at other PET facilities in the future.

Explore moreWe are working with several industry partners and organizations, which have a joint commitment to improve plastic waste management, which lead to a circular economy for sustainable plastics.

The New Plastics Economy: IVL is proud to announce its commitment as part of the New Plastics Economy to eliminate problematic plastic packaging, and increase the use of recycled plastic in packaging. The commitment calls on companies and governments to innovate solutions enabling plastic to be 100% reusable, recyclable, or compostable.

Global Plastic Action Partnership: IVL announced that it has joined the World Economic Forum’s Global Plastic Action Partnership (GPAP), which aims to reduce plastic leakage into the environment and is driving the transition to a circular economy for plastics. This partnership is aligned with Indorama Ventures 2019 commitment to increase recycled content volumes of PET by at least 750,000 tonnes, pledging US$ 1.5 billion towards achieving this target by 2025.

The Recycling Partnership: IVL announced that it has joined the Recycling Partnership, the only organization in the United States that engages the full recycling supply chain. IVL’s collaboration with The Recycling Partnership will promote the U.S. residential recycling rates and increase availability of recycled PET to meet the global recycled content commitments.

We strongly support the global efforts underway to achieve the UN Sustainable Development Goals (SDGs). Our recycling efforts are particularly focused on addressing the following SDGs:

Indorama Ventures becomes the first company in Thailand to produce high standard recycled PET fibers to manufacture Level 3 reusable isolated gown PPE suits for medical personnel during the COVID-19 pandemic, working in collaboration with Less Plastic Thailand, Thai Taffeta, T-Plus, TOA Paint and GoWith20. The PPE suits are made from PET bottles collected in Thailand through various organizations and recycled into fibers at our facility in Nakhon Pathom.

Explore moreWe established Indorama Ventures Investments & Holdings (IVIH), our start-up business incubator, which invests in start-up businesses driving advancements in recycling, bio-based chemicals and polymers, renewable feedstock, and biodegradable polymers. We have already identified 30 projects with the potential to deliver on these commitments. Through the employment of circular feedstocks, IVL can reduce hazardous waste generation, fossil feedstock consumption, and greenhouse gas emissions, making it a key strategy for embracing circularity.

As part of a supply chain collaboration with Suntory, ENEOS Corporation, Mitsubishi Corporation, Iwatani, and Neste, the world’s first bio-PET bottle for commercial scale will be launched, made from ISCC+ certified bio-paraxylene.2 This collaboration marks a significant milestone in the journey toward sustainable packaging, introducing PET bottles derived from used cooking oil. PET bottles made with this technology can significantly reduce the CO2 emissions of products.

The collaboration will launch approximately 45 million PET bottles for Suntory’s selected beverages in Japan made with this innovative material3 , with further introduction of other products to be considered in the future. With this number of PET bottles on the markets, we could divert 0.5 million tons of PET waste from landfills, reduce 0.4 million tons of carbon footprint, and make around 600 million USD of sales revenue4. By combining the expertise and resources of industry leaders across the value chain, this initiative underscores the power of collaboration in addressing global sustainability challenges.

1 As of October 28, 2024. Based on research by ENEOS Corporation and Mitsubishi Corporation.

2 The mass balance approach is applied. Under this approach, for a product manufactured by mixing a material with a specific characteristic with materials lacking that characteristic, the characteristic can be allocated to a portion of the product’s output in proportion to the amount of the material with the characteristic used in the production process. The mass balance approach has been ISCC+ certified.

3 280 ml and 285 ml PET bottles.

4 Estimated based on the average selling price of rPET resin in the Singapore market in 2024

Explore MoreIndorama Ventures joins the world’s first1 supply chain established for more sustainable polyester fiber Renewable and bio-based materials, as well as materials produced via carbon capture and utilization (CCU para-xylene)2 will be used in the manufacturing of polyester fibers for THE NORTH FACE brand in Japan, instead of fossil-based materials. Alongside Indorama Ventures representing Thailand, the project parties involved in the pilot are Goldwin (the project owner), Mitsubishi Corporation, Chiyoda Corporation (all three from Japan), SK geocentric (South Korea), India Glycols (India), and Neste (Finland).

1 This refers to the first time CCU para-xylene (direct synthesis from CO2 ) is applied as well as the first-time polyester is made without the use of fossil materials, through collaboration among upstream material companies and a downstream apparel company through mass balancing, according to the companies’ research.

2 Regarding the production of para-xylene derived from CO2 as a raw material, the University of Toyama, HighChem Company Limited, Nippon Steel Engineering Co. Ltd., Nippon Steel Corporation, Chiyoda Corporation and Mitsubishi Corporation were awarded a NEDO project in 2020 (New Energy and Industrial Technology Development Organization) for “Technology Development for Carbon Recycling and Next-Generation Thermal Power Generation/Technology Development for CO2 Emission Reduction and Effective Utilization” and are conducting joint research and development. This project aims to supply CO2-derived para-xylene on a trial basis, which has been produced during the operation of a pilot plant installed at Chiyoda Corporation’s Koyasu Research Park since March 2022.

Explore MoreIndorama Ventures has partnered with the “Trash Lucky” to promote sustainable waste management and improve the livelihoods of local waste collectors. Leveraging its expertise in recycling and waste management, the company supported the development of training manuals for waste collectors and helped enhance recycling processes and standards.

In 2024, the project successfully recovered 3 tons of post-consumer PET bottles, which were recycled through Indorama Ventures’ own facilities. This initiative helped reduce production costs and avoided greenhouse gas emissions from landfill disposal. Moreover, it positively impacted local communities by creating 199 job opportunities for waste collectors in Bangkok. The collaboration showcases the power of partnership in driving a circular economy and delivering tangible environmental and social benefits.

Explore Moreอินโดรามา เวนเจอร์ส ร่วมกับ บริษัท ไทยวาโก้รณรงค์ให้ประชาชนร่วมลดขยะชุมชน ด้วยการคัดแยกขวด PET และรวบรวมมาบริจาคให้กับไทยวาโก้ โดยตั้งเป้าแปรรูปขวดพลาสติกเดือนละ 1 ตันหรือเทียบเท่าขวดน้ำ ดื่มขนาด 600 มิลลิลิตร จำนวนกว่า 45,000 ขวด ต่อเนื่องเป็นเวลาอย่างน้อย 3 ปี

ทั้งนี้ อินโดรามา เวนเจอร์ส จะนำขวดพลาสติกมารีไซเคิลและแปรรูปเป็นเส้นด้ายคุณภาพสูง ซึ่งสามารถนำมาผลิตเป็นผลิตภัณฑ์และสินค้าต่างๆ ในเครือวาโก้ ภายในแนวคิด Eco Bra

Explore More